TRR770 is an innovative industrial roll-to-roll and flatbed UV-LED inkjet printer with small footprint and superior performance, specially designed for high-quality colorful label printing. TRR770 supports simultaneous printing of dual rolls perfectly to boost print productivity dramatically. With the capabilities of white and varnish ink printing, TRR770 enables you to print appealing finishing effects on transparent, colored or metallic media. TRR770 supports the printing of most label materials widely used in food, beverages, pharmaceuticals, and household chemical products, bringing you more business opportunities and potential profits. TRR770 is the best choice for short-run label printing, customized label printing and proofing of labels.

TRR770

TRR770 TRR770

TRR770 TRR770

TRR770 TRR770

TRR770

|

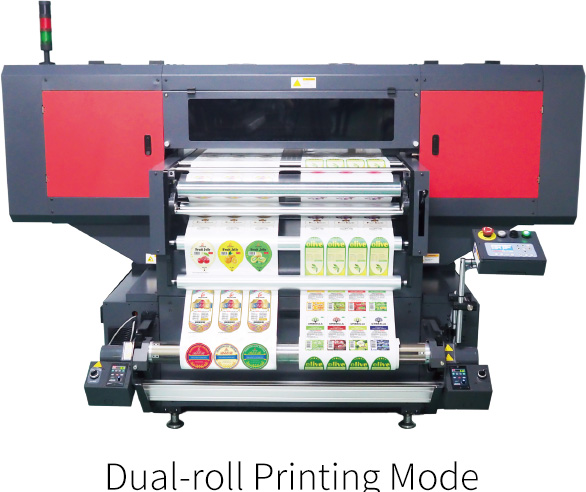

Simultaneously printing of two separate rolls

● Different width rolls

● Different diameter rolls

● Different media

● Different jobs

Batch printing on souvenirs, personalized and promotional products

With Flatbed Printing mode, TRR770 is an ideal solution for printing multiple small-sized objects simultaneously, even with different artworks. The fixture can be placed on the flatbed table to quickly position small-sized objects. The ColorPRINT RIP software allows to customize “template” according to the fixture and define each image. The real-time preview achieves what you see is what you print.

|

TRR770 is equipped with industrial DOD piezoelectric inkjet print heads featuring 600dpi physical resolution and minimum 7pl droplet with high jetting frequency.

Amica’s proprietary VDS (Variable Droplet Size) control technology combines the print head control of 1 to 3 levels of ink droplet sizes and ColorPRINT RIP software, producing vivid colors, smooth gradients, as well as crisp and clear small-sized texts and lines, providing you with high-quality final label prints.

|

| Variable Droplet Size Control |

TRR770 supports colorful variable data printing, including texts, numbers, time, serial numbers, QR codes, etc., which can be varied without stopping or slowing down the printing.

With TRR770, you can customize the printing content according to customers' requirements and apply it to the printing of personalized labels. Variable data printing helps you create added value applications and enhance market competitiveness.

|

Varnish ink printing provides versatile surface finishes with amazing tactile and visual effects to beautify the appearance of labels and grasp viewers’ attention. The overall label can be covered with a gloss/ matte finish to offer a similar look as lamination; or glossy/ matte spot varnish can be added to some specified appealing parts to highlight important details, such as logos, slogans or special designs.

Moreover, embossed effects can be attained by laying down multiple layers of varnish ink. Overprint varnish also prevents labels from yellowing, fading, cracking, peeling, flaking, etc.

|

| Label with a gloss finish |

|

| Label with a matte finish |

|

| Label with spot varnish |

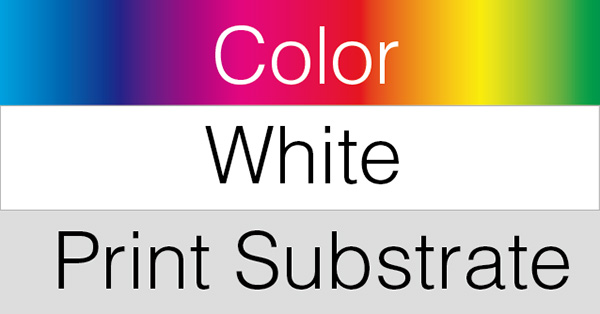

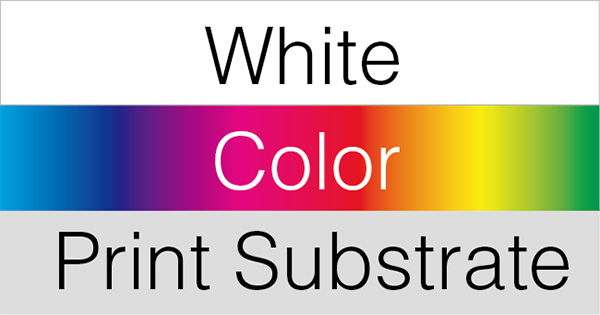

Amica’s high density white ink delivers vibrant and exceptional image quality on transparent, colored or metallic labels with less ink consumption. White ink can be applied as a base or over layer printed to obtain labels with vivid colors and bright images. By controlling the amount or number of white ink layers, varying levels of opacity can be also achieved which will endow printed images with rich layers and a stereo impression.

The separate white ink circulation system keeps the white ink properly mixed continuously for consistent and stable print quality.

| Under-Printing | Over-Printing | |

| Print white ink at the area of job |

|

|

| Print white ink at the area of image |

|

|

| Print white ink and color inks individually |

|

|

|

LCD Smart Panel User friendly color LCD Smart Panel provides printer status information and offline printer control. |

|

Automatic Ink Supply System Automatic Ink Supply System monitors and controls the ink levels of the main/ sub ink tanks with liquid level sensors. The alarm will be automatically triggered for ink shortage or overflows. |

|

Active Negative Pressure System An Active Negative Pressure System with digital control pressure display gauges ensures high-quality printing at higher possible firing frequency of ink jet printing with industrial piezo print heads. |

|

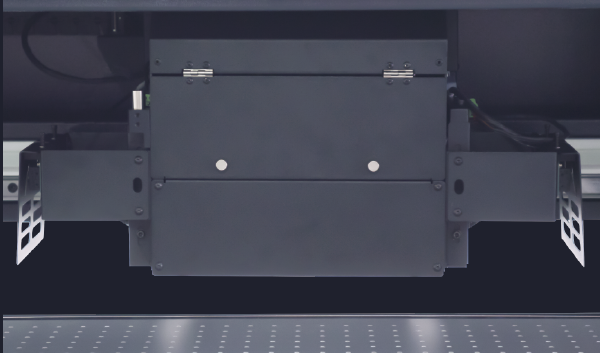

Print Head Maintenance Module Based on an all-in-one design concept, the small and compact Print Head Maintenance Module allows automatic purging, wiping and capping for convenient unattended operation. |

| Print Head Model | MH5420 | |||

| Number of Print Heads | 2 | 3 | 4 | |

| Number of Colors | CMYK | WW + CMYK | WW + CMYK + VV | |

|

Productivity in Roll-to-roll

Print Mode Unit: m²/ hr. (ft²/ hr.) |

720 × 600dpi, 4 pass |

15.6 (168) | 15.1 (163) | 6.5 (70) |

|

720 × 900dpi, 6 pass |

11.6 (125) | 11.0 (118) | 5.1 (55) | |

|

Productivity in Flatbed

Print Mode Unit: m²/ hr. (ft²/ hr.) |

720 × 600dpi, 4 pass |

12.4 (133) | 11.9 (128) | 6.5 (70) |

|

720 × 900dpi, 6 pass |

10.1 (109) | 9.2 (99) | 5.1 (55) | |