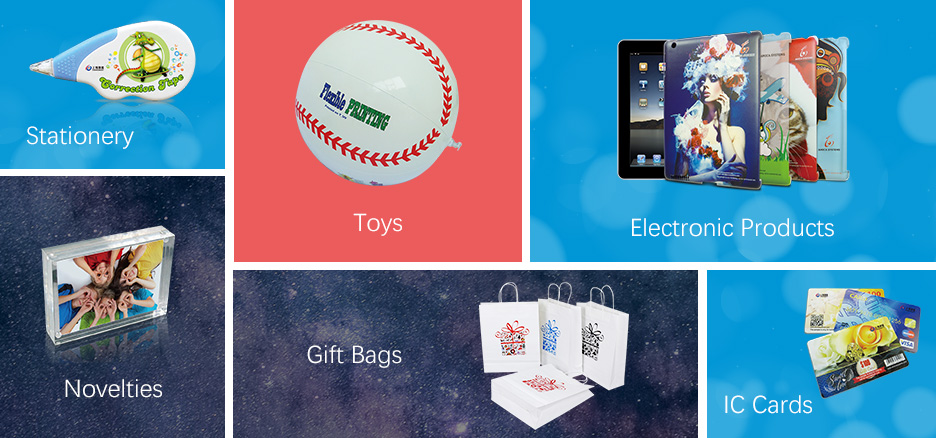

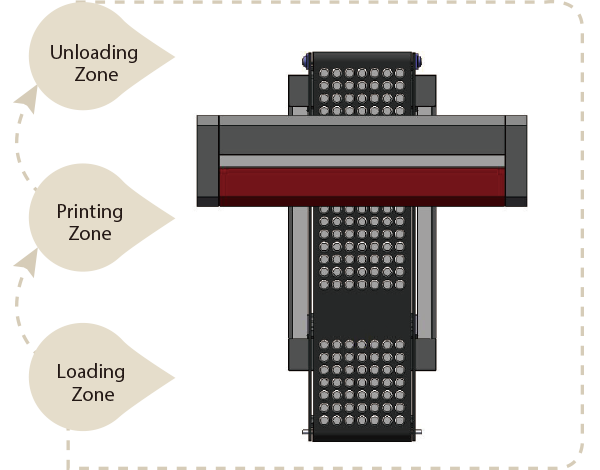

TC series printer is designed for high-speed print production of 3-Dimension objects and flat items. TC series printer improves productivity of short- and long-run print jobs featuring multiple operation zones for loading, printing and unloading.

Efficient workflow enhancements increase productivity and reduce time, cost and effort. TC series printer is the best choice for personalized print decorations

TC500/ TC800/ TC800 EH

TC500/ TC800/ TC800 EH TC500/ TC800/ TC800 EH

TC500/ TC800/ TC800 EH TC500/ TC800/ TC800 EH

TC500/ TC800/ TC800 EH TC500/ TC800/ TC800 EH

TC500/ TC800/ TC800 EH

|

Compared to traditional printing methods, such as pad printing and screen printing, TC series delivers minimal setup time, no pre-press time and lower consumables costs. TC series eliminates the need for films, plates and screens. It also reduces the cost of ink.

State-of-the-art dual UV-LED lamps ensure ink curing for high speed printing. And UV-LED lamps have instant On/Off capability so that printing and curing are synchronized efficiently.

|

| Variable Droplet Size Control Technology |

|

|

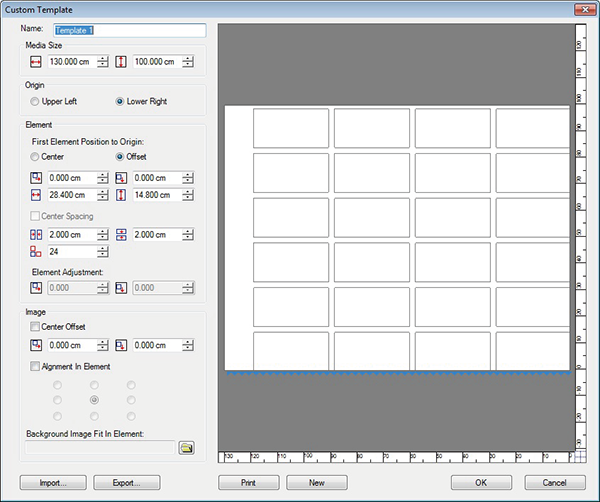

| Custom Template | Template Printing |

The TC printer is an ideal solution for printing same or different images on a large number of small-sized substrates. Template can be placed on the flatbed table to quickly position small-sized substrates. The ColorPRINT RIP software allows to customize “template” according to the size of the real template and define the print quantity of each image. The real-time preview makes sure what you see is what you print.

Thanks to the full adjustable Z-axis height design and UV-LED curable technology, TC800 EH owns the ability to print on virtually any substrates between 260mm and 460mm thick, realizing outstanding print quality and versatile applications on one device at a fraction of cost and time.

TC800 EH will give you competitive advantages and open your business up to opportunities in custom items, such as corrugated boards and suitcases.

|

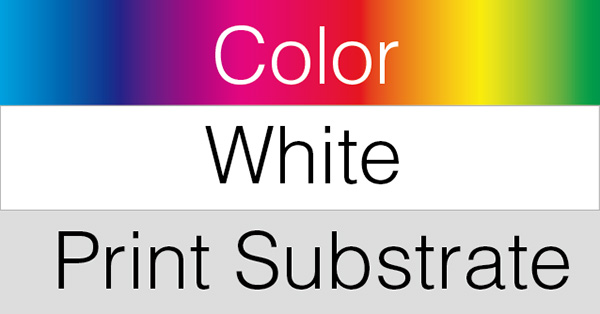

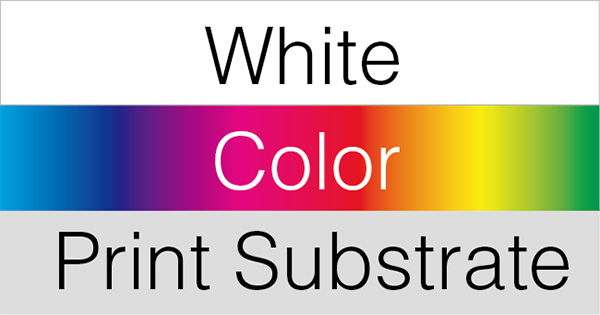

Even printing at a single print pass with the high density white inks, TC series perfectly offers vivid and accurate colors on transparent, light, and dark media. Meanwhile, the ability to print on a wide variety of media up to 150mm, 260mm or 460mm thick expands your business.

Thanks to the separate white ink circulation system, TC series easily keeps the white ink properly mixed at all times for consistent and reliable printing.

| Under-Printing | Over-Printing | |

| Print white ink at the area of job |

|

|

| Print white ink at the area of image |

|

|

| Print white ink and color inks individually |

|

|

|

The all-in-one Print Head Maintenance Module allows automatic purging, wiping and capping for unattended operation. |

|

The 3L ink tanks with liquid level sensors alarm for the shortage of ink. |

|

User friendly color LCD Smart Panel provides printer status information and offline printer control. |

|

An Active Negative Pressure System ensures high-quality printing at higher possible firing frequency of inkjet printing with industrial piezo print head. |

| TC500 | TC800 | TC800 EH | |

| Maximum Print Zone (W × D) | 500mm × 600mm (19.7" × 23.6") | 800mm × 640mm (31.5" × 25.2") | 800mm × 640mm (31.5" × 25.2") |

| Loading Zone Size (W × D) | 500mm × 600mm (19.7" × 23.6") | ||

| Unloading Zone Size (W × D) | 500mm × 600mm (19.7" × 23.6") | ||

| Dimensions (W × D × H) |

2100mm × 1730mm × 1340mm (83" × 68" × 53") |

2181mm × 2363mm × 1490mm (85.9" × 93" × 58.7") |

2181mm × 2363mm × 1690mm (85.9" × 93" × 66.5") |

| Net Weight | 470kg | 620kg | 650kg |

| PRODUCTIVITY | |||||

| Printer Model | TC500 | TC800/ TC800 EH | |||

| Print Head Model |

MH2420; 7pl, 14pl, 21pl, Variable Droplet Size Control Technology |

MH5420; 7pl, 14pl, 21pl, Variable Droplet Size Control Technology |

|||

| Number of Heads | 4 | 6 | 2 | 3 | |

| Number of Colors | CMYK | WW + CMYK | CMYK | WW + CMYK | |

|

Productivity Unit: m²/ hr. (ft²/ hr.) |

1200 × 600dpi,4 pass | 9.6 (103) | 9.2 (99) | 22.4 (241) | 21.1 (227) |

| 1200 × 900dpi,6 pass | 7.1 (76) | 6.8 (73) | 16 (172) | 14.6 (157) | |