LPS330 is an advanced, versatile and cost-effective UV-LED inkjet printer, which aims to meet the needs of various printing applications. The highly engineered and compact design of LPS330 integrates the functions required for packaging and specialty labels, industrial decoration, and variable data printing.

As an all-in-one printer, LPS330 has the tools you need to enter the digital printing world. Not only can you enjoy the photographic image quality that benefits from the multi-pass scanning printing technology, but you can also obtain higher printing effciency than ever with a single print swath up to 320 mm (12.6 in). LPS330 is an ideal choice for responding to the growing demand for personalized printing, custom printing, and sample printing.

LPS330

LPS330 LPS330

LPS330 LPS330

LPS330 LPS330

LPS330

| In flatbed printing mode, LPS330 allows users to print directly on rigid substrates and supports different templates for different items, such as stationery, cards, gifts, and novelties. |

|

|

| In roll-to-roll & flatbed printing mode, LPS330 allows you to produce eye-catching, distinctive prints for a wide range of applications. |

|

|

2.5D printing enables you to achieve remarkably rich and special effects ranging from gloss or matte finishes for overall or only appealing parts, to texture or embossed effects. LPS330 also supports to build up raised ink layers on a wide range of thick substrates.

|

|

|

|

|

| NuviPRINT® Main Window with Variable Data List | Printer Control Software | Code 39 |

|

For higher print productivity, the wide shuttle carriage supports up to 18 print heads and 6 color channels to achieve 320 mm print width per print swath. |

|

During high-speed production, the vacuum table keeps the substrate stationary and flat to obtain precise color registration. |

|

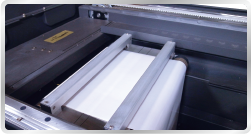

The splicing table facilitates fast roll switching, reducing downtime and material waste. |

|

Based on the all-in-one design concept, the small and compact print head maintenance module allows automatic purging, wiping and capping. |

|

Using the integrated technology including servo drive control, tension control, and automatic deviation correction, LPS realizes high-precision media feeding. |

|

The CCD vision system can quickly identify black positioning marks to accurately overprint varnish patterns, variable data or images on the preprinted roll. |

LPS330 works seamlessly with the NuviPRINT® PDF RIP software and Printer Control Software for high-productivity and versatile printing. The enhanced production workflow not only implements a streamlined approach, but makes predictable and high-quality output as well.

| Print Resolution | Color Modes | Number of Print Heads | Ink Types | Image Size | Print Productivity* | |

| Unit: sqm/ hr | Unit: sqft/ hr | |||||

| 720 × 600 dpi |

CMYK or CMYKLcLm |

12 (2 × 6) or 18 (3 × 6) |

UV curable ink | 1100 × 320 mm | 144 | 1550 |

| 720 × 900 dpi | 115 | 1237 | ||||

| 720 × 600 dpi |

CMYK + WW or CMYK + VV |

18 (3 × 6) | 67 | 723 | ||

| 720 × 900 dpi | 48 | 516 | ||||

|

Packaging and Specialty Labels

|

Decorations

|

Variable Data Printing

|