TBC/ TB industrial color UV-LED inkjet printers are specially engineered for direct printing on tapers/ cylinders, such as cups, bottles, tins and cans,

and support a wide range of materials, including metal, glass, paper, wood and plastic.

Thanks to professional color management technology and proprietary VDS (Variable Droplet Size) control technology, TBC/ TB is specialized in producing smooth gradients, vivid images, and crisp small-sized text on tapers/ cylinders.

Highlighted by simplified workflow and easy operation, TBC/ TB boosts up the print productivity, earning the reputation as an ideal choice for various emerging markets in short-run printing, customized and personalized printing, package proofing applications, etc.

TBC/ TB

TBC/ TB TBC/ TB

TBC/ TB

Compared with traditional taper/ cylinder printing, like pad printing, screen printing and label printing, TBC/ TB printers have prominent advantages in being free from plates, fast warm-up, short turnaround time, as well as customized printing.

Also superior to digital thermal transfer printers, TBC/ TB printers own more simplified workflow, easier operation and lower cost.

TBC/ TB printers are specialized in producing smooth gradients and vivid images on tapers/ cylinders, not being achieved with other printing technologies.

Thanks to the Rotational Print Pass Method (RPPM) and Special Print Head Arrangement Method for taper/ cylinder printing, TBC/ TB printers are endowed with amazing print speeds and quality.

The Ink Droplet Compensation Algorithm is specially developed for taper printing, ensuring even image density on different diameter sections of the taper and avoiding image deformation.

When printing the same text, graphic or image onto cylinders of different diameters, the Ink Droplet Conversion Algorithm realizes consistent resolutions and stable visual effects, ideal for printing bottle/ cup sets with identical patterns and colors but in different sizes.

Combining special algorithms with real-time monitoring and feedback, TBC/ TB printers effectively eliminate gaps or overlaps of images in 360° seamless printing.

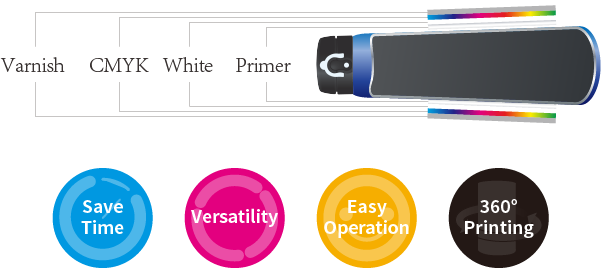

TBC/ TB printers support printing Varnish for varied surface decorations of attractive tactile or visual effects; printing Primer for enhanced adhesion on different materials; and specialty ink colors for matching corporate logos and recognizing colors.

The White Ink Circulation System keeps the White ink properly mixed for solid covering and coloration. Combined with proven color management technology, TBC/ TB printers easily achieve durable, vivid and bright colors on colored or black tapers/ cylinders.

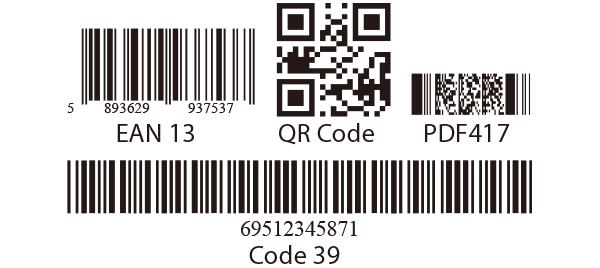

TBC/ TB printers support colorful variable data printing, including texts, numbers, time, serial numbers, QR codes, etc. TBC/ TB printers help you create added value applications and obtain more business opportunities for personalized packaging, promotional items or product decoration printing.

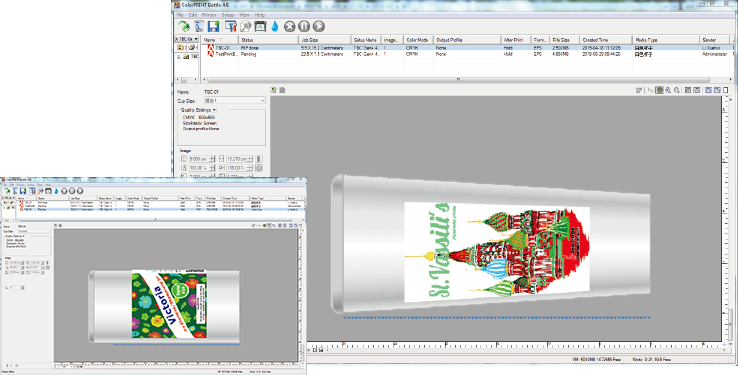

ColorPRINT Bottle RIP Software |

|

|

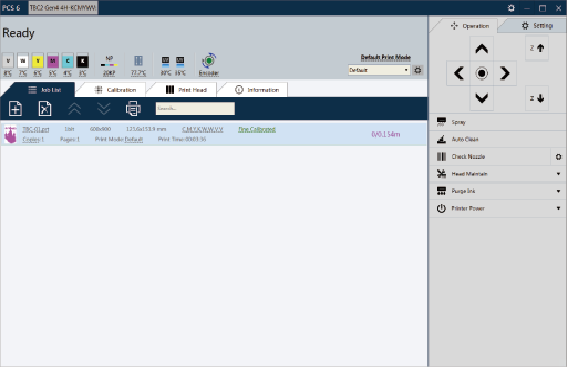

Printer Control Software (PCS) |

|

|

| TBC | TBC/ TB |

|

|

|

Based on an all-in-one design concept, the small and compact Print Head Maintenance Module allows automatic purging, wiping and capping for convenient unattended operation. |

|

Positioning Sensors indicate the position of the print object and enable to quickly set the printing area, achieving efficient and precise printing. |

|

Automatic Print Head Protection System monitors whether the print heads will be scratched or exposed to UV lights, and immediately stops the movement of the carriage in case of the emergency situations,effectively ensuring the safety of print heads. |

| Printer Model | TBC | TB | |

| Printed Object | Shape | Taper/ Cylinder | Cylinder |

| Size |

Length: 110 - 270mm (4.33" - 10.63") Top diameter: 40 - 120mm (1.57" - 4.72") Bottom diameter: 40 - 120mm (1.57" - 4.72") |

Length: 110 - 270mm (4.33" - 10.63") Diameter: 40 - 120mm (1.57" - 4.72") |

|

| Rotary Degree of Object | 360° | ||

| Printable Size |

Feeding direction (R-axis): entire surface of the objects Print head moving direction (Y-axis): within 220mm |

||

| Printer Dimensions (W × D × H) | 1373mm × 670mm × 1654mm (54.1" × 26.4" × 65.1") | ||

| Bottle Diameter | Image Size | Print Resolution | Color | Productivity | |

| Production Mode | Quality Mode | ||||

| 70mm (2.76") | 60mm × 219.8mm (2.36" × 8.65") | 600 × 900dpi | CMYK | 16 sec. | 23 sec. |

| CMYK + W | 20 sec. | 28 sec. | |||

| CMYK + W + V | 26 sec. | 39 sec. | |||

| 100mm × 219.8mm (3.94" × 8.65") | 600 × 900dpi | CMYK | 22 sec. | 34 sec. | |

| CMYK + W | 28 sec. | 41 sec. | |||

| CMYK + W + V | 37 sec. | 58 sec. | |||