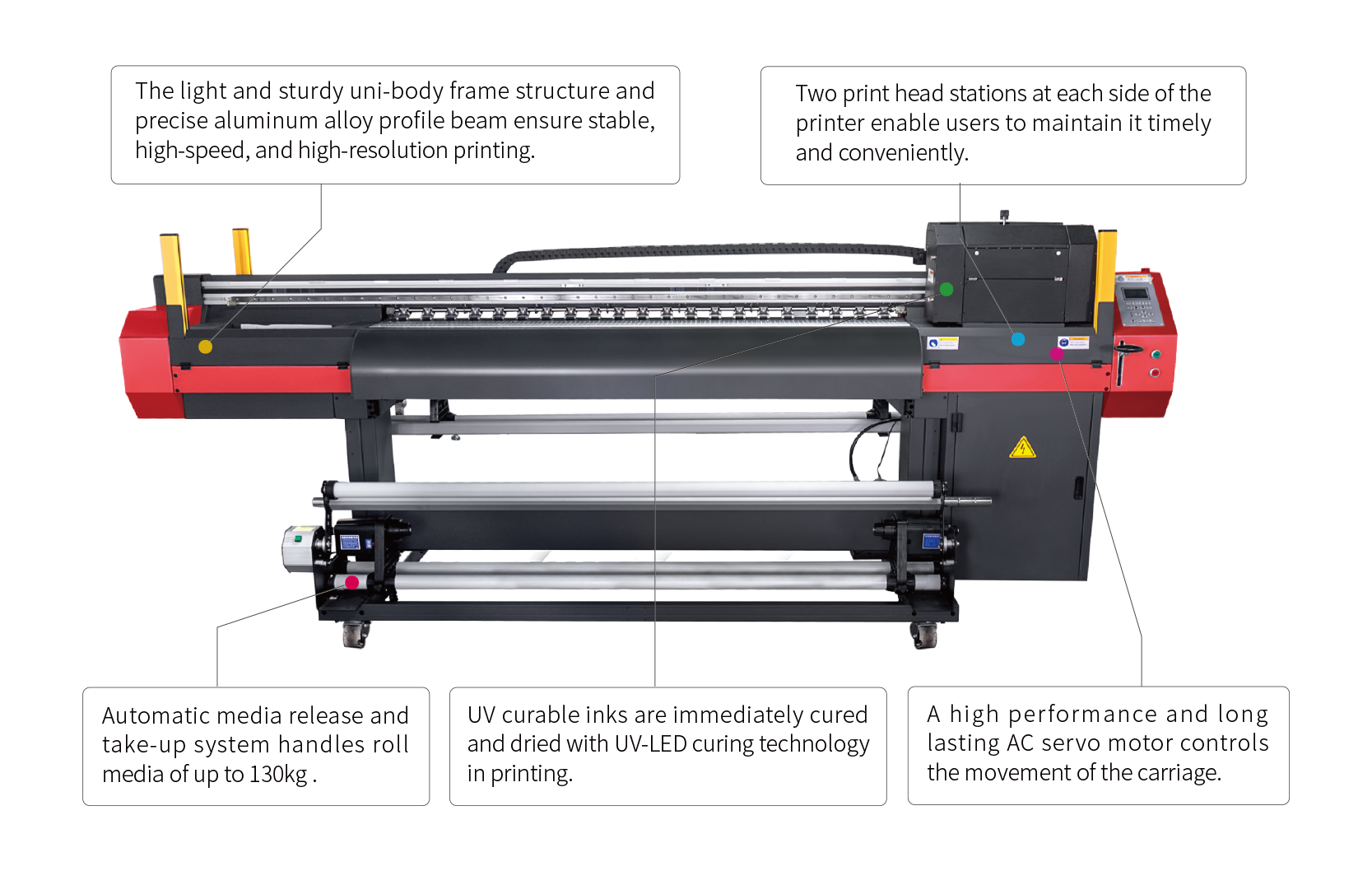

SL16 is an innovative environment-friendly UV-LED inkjet printer, specially designed to print large-format indoor and outdoor signs and displays. With flexible media handling system and UV-LED curing technology, SL16 enables to directly print exceptional images on a wide variety of roll media and rigid substrates, including vinyl, banner,fabrics, card boards, carton boards, foam boards, etc. To help expand your revenue-producing opportunities, SL16 offers superior white and varnish ink printing for appealing finishing effects on transparent or colored media.

SL16

SL16 SL16

SL16 SL16

SL16 SL16

SL16

Utilizing the most advanced DOD piezoelectric print heads, SL16 printer combines excellent print quality and high efficiency with exquisite image output. The print heads feature up to 600dpi physical resolution, minimum 4pl ink drop size, high jetting frequency, and support grayscale printing.

Proprietary VDS (Variable Droplet Size) control technology integrates print head control of 3-level droplet sizes with ColorPRINT RIP software for producing sharper images with smoother gradients.

|

| VDS Control Technology |

SL16 accepts both flexible roll media and rigid substrates from films to boards, enabling you to expand your business with various applications of high printing quality. Thanks to the roll-to-roll release & take-up system, SL16 easily handles any wide-format roll media within 130kg weight. While with an optional foldable supporting table, it supports printing on rigid substrates up to 10mm thick and 12kg with a minimal footprint.

|

|

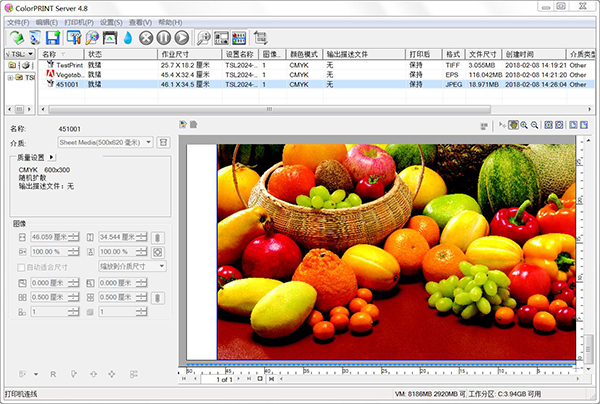

| ColorPRINT RIP Software | Printer Control Software (PCS) |

Proprietary image algorithm enables you to print large-size images reliably without stopping.

Working seamlessly with the professional ColorPRINT RIP software, SL16 printer produces vivid colors and fine details with ColorPRINT’ s enhanced color management and raster image process technology to grab viewers’ attention.

Printer Control Software (PCS) offers a user-friendly interface to interactively control the printer, monitor printer status, and set printer options, such as the amplitude and pulse width of jetting waveforms and the temperature for each print head.

UV-LED technology has significant advantages in energy usage, reduced heat load to the substrate, smaller equipment footprint. UV-LED lamps can safely irradiate on heat sensitive media, including foam board, foils, PVC. Using UV-LED lamps, a smaller equipment footprint can be used for stable and reliable printing. UV-LED lamps have a long life cycle for consistent print quality.

UV-LED technology is a true earth friendly solution that does not require the use of mercury and produces no ozone. UV-LED lamps do not emit UVC rays and there is no risk in bulbs breaking.

UV-LED lamps have the capability of Instant On/Off so that users can start printing immediately after starting up the UV-LED printer.

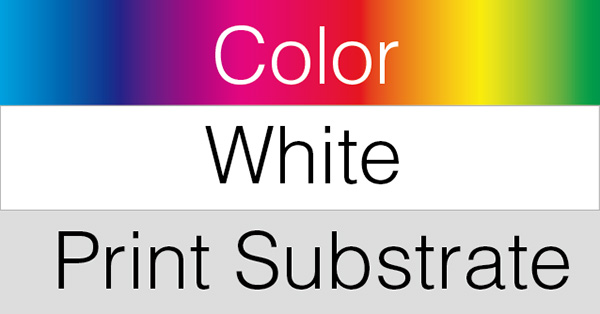

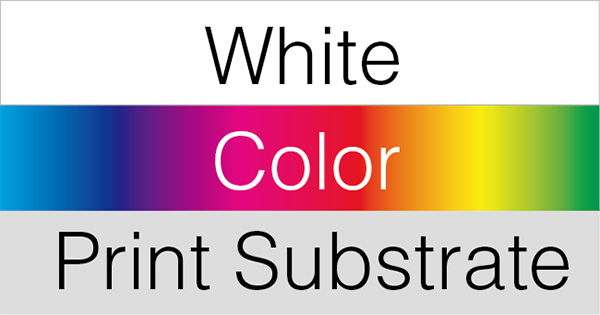

Printing with the high density white inks, SL16 offers bright and vivid colors on transparent and colored media. Thanks to the separate white ink circulation system, SL16 easily keeps the white ink properly mixed at all times for consistent and reliable printing.

Coming with professional ColorPRINT RIP software, SL16 enables over-printing for backlit applications on transparent materials, under-printing for colored materials, printing white out of images, or printing white as a spot color.

| Under-Printing | Over-Printing | |

| Print white ink at the area of job |

|

|

| Print white ink at the area of image |

|

|

| Print white ink and color inks individually |

|

|

|

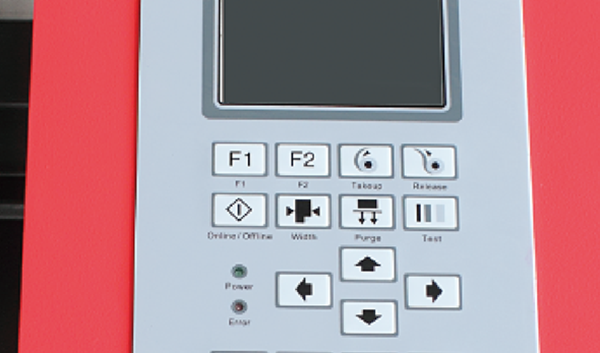

Color LCD Smart Panel provides printer status information and online/ offline printer control. |

|

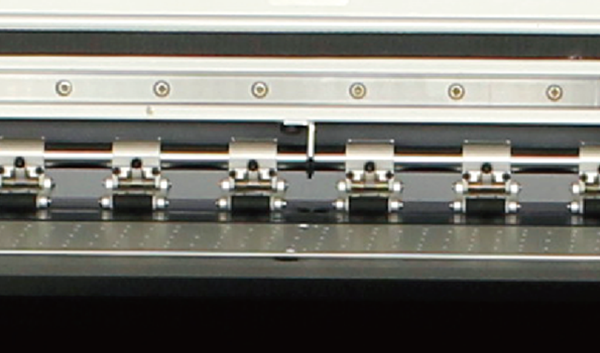

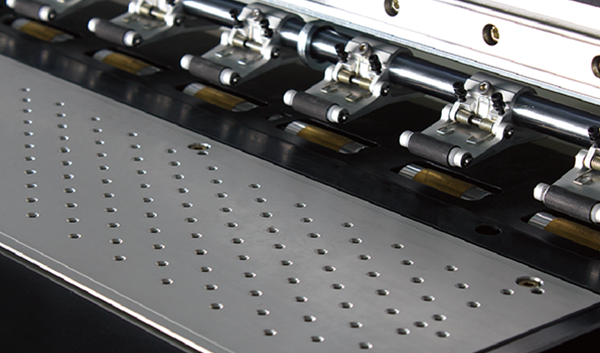

Silent linear guide and linear guide girder ensure precise printing and easy operation. |

|

1.5L bulk ink tanks with liquid level sensors are easily used for adding ink and alarm for the shortage of ink. |

|

The vacuum platen with pinch rollers ensures the perfect straightness of media feeding. |

| PRODUCTIVITY | |||||||

| Print Head Model | MH2420 | MH5420 | Kyocera KJ4 | ||||

| Number of Heads | 2 × 4,2 × 6 | 2 Rows, 4 or 6 Heads 0.5 × 2 × 4 or 6 Colors | 1 Row, 3 Heads 0.5 × 1 × 6 Colors | ||||

|

Productivity Unit:m²/ hr. (ft²/ hr.) |

600 × 900dpi,3 pass+ | 41 (441) | 63 (678) | 55 (592) | |||

| 1200 × 600dpi,4 pass+ | 33 (355) | 54 (581) | 44 (474) | ||||

| 600 × 900dpi,6 pass+ | 23 (248) | 41 (441) | 34 (366) | ||||

| 1200 × 600dpi,8 pass+ | 18 (194) | 32 (344) | 26 (280) | ||||