CRL33 wide-format UV-LED inkjet printer is a great contribution to the roll-to-roll printing market. CRL33 supports simultaneous printing of dual rolls to boost print productivity dramatically. The release and take-up system enables stable and precise advancement of ultrathin flexible substrates for high quality printing. The white ink function brings about possibilities for printing bright and vivid colors on transparent or colored materials. UV-LED curing system allows higher production capacity with lower energy, costs and time.

CRL33 combines high quality with high productivity on a vast array of flexible media including soft films for indoor and outdoor applications. With the highly reliable CRL33, you can not only produce traditional jobs as you do today, but open up new revenue resources with a variety of newly-developed application offerings.

CRL33

CRL33 CRL33

CRL33 CRL33

CRL33 CRL33

CRL33

|

| Variable Droplet Size Control Technology |

CRL33 is equipped with industrial DOD piezoelectric inkjet print heads featuring 600dpi physical resolution and minimum 7pl droplet with high jetting frequency.

The VDS (Variable Droplet Size) control technology integrates the print head control of 3-level different droplet sizes with the ColorPRINT RIP software for producing sharp images with smoother gradients.

CRL33 supports simultaneous printing of dual rolls to dramatically boost print productivity. You can print two jobs on two separate rolls at the same time. The width of each roll can be configured flexibly with an overall media width of up to 3.0m (118"). The feature tailors each print job to the needs and expands applications of the printer greatly.

|

|

Utilizing environment-friendly UV-LED curing technology, CRL33 supports a wide range of flexible materials including soft films which may be too sensitive for latex or solvent systems requiring heat to dry the ink.

With multiple significant technological advantages, CRL33 achieves individualized productions of advertising displays or building decorations, especially for making backlit light box films, suspending ceilings, soft film covers for sliding doors, and even fashion crafts.

The release and take-up system of the CRL33 printer is specially designed for handling the advancement of ultrathin flexible substrates on a wide-format inkjet printer. The effective media path makes it easy to load heavy rolls tightly and straightly. It also ensures the steps of the substrates are constant and completely avoids the touch between the print head and the substrate.

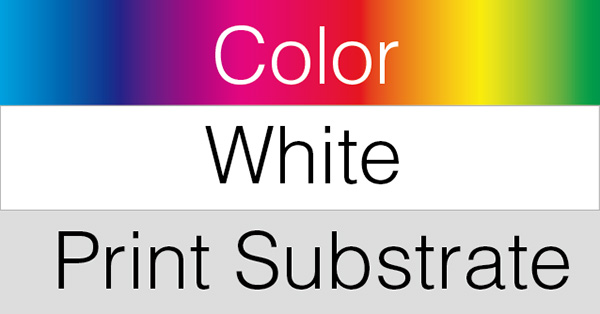

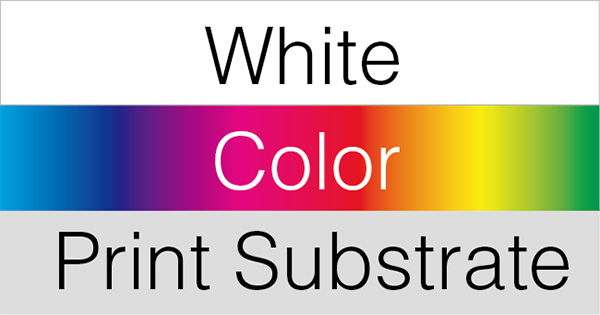

Printing with the high density white ink, CRL33 offers bright and vivid colors on transparent and colored media. Thanks to the separate white ink circulation system, the CRL33 printer easily keeps the white ink properly mixed at all times for consistent and reliable printing.

Coming with professional ColorPRINT RIP software, the CRL33 printer enables over-printing for backlit applications on transparent materials, under-printing for colored materials, printing white out of images, or printing white as a spot color.

| Under-Printing | Over-Printing | |

| Print white ink at the area of job |

|

|

| Print white ink at the area of image |

|

|

| Print white ink and color inks individually |

|

|

|

An Active Negative Pressure System ensures high-quality printing at higher possible firing frequency of inkjet printing with industrial piezo print head. |

|

The all-in-one Print Head Maintenance Module allows automatic purging, wiping and capping for unattended operation. |

|

Vacuum Platen and Pinch Rubber Rollers ensure the expected straightness of media feeding. Silent Linear Guide and Linear Guide Girder ensure accurate printing. |

|

User friendly color LCD Smart Panel provides printer status information and offline printer control. |

| PRODUCTIVITY | |||||

| Print Head Model | MH5420 | ||||

| Number of Heads | 4 | 5 | |||

| Colors | CMYK | WW + CMYK | |||

|

Productivity Unit:m²/ hr. (ft²/ hr.) |

600 × 900dpi,3 pass | 96.8 (1042.0) | - | ||

| 1200 × 600dpi,4 pass | 76.8 (826.7) | 41 (441.3) | |||

| 1200 × 900dpi,6 pass | 52.8 (568.3) | 29.5 (317.5) | |||